Safety and environmental impact are two of the most important aspects of any industrial operation. Known as health, safety and environment (HSE), they are a fundamental concern of any industry.

However, oil exploration and production projects are quite susceptible to issues raised by governments and environmental groups.

We witnessed the HSE component development in Oil & Gas projects. Policy and procedures in this area have become an integral part of Oil companies’ management.

Aquifers contamination, rig accidents, and oil spills on the sea and shore constitute the main environmental problem linked to this industry. The uncontrolled release of a given volume of hydrocarbons into the sea immediately affects marine fauna and flora, as well as the tourism and fishing industries.

All oil companies follow strict operating procedures which, if followed, minimize the risk of accidents. This risk will always be present, so good response plans with the ability to limit environmental impact as effectively and quickly as possible are mandatory; in addition, demanding regulatory and enforcement systems are also crucial.

In short, when implementing a HSE management system, companies must focus on not only their economic interests, but also on people, communities and the environment.

EQS provides a wide range of environmental consulting services including environmental impact studies, environmental monitoring and licensing, environmental and HSE audits in accordance with applicable regulations. These services are mainly intended for the industrial, oil and gas and energy sectors.

One of the main tools of Environmental Management is the Environmental Impact Assessment, whose main objective is to assess the impacts that certain public and private projects may have on the environment, based on previously developed Environmental Impact Studies.

These studies should focus on projects that, by their nature, size or location, may have implications on environmental and social balance and harmony, so that the Environmental Impact Assessment becomes an effective instrument for environmental protection and management, as well as ensuring fair and balanced decisions by the public administration.

The Environmental Impact Study (EIA) is the document prepared under the Environmental Impact Assessment procedure, which contains a brief description of the project, the identification and assessment of the likely positive and negative impacts that the project’s implementation may have on environment, as well as the proposed mitigation measures and a program for monitoring and monitoring the identified impacts.

Undoubtedly, environment is one of the most visible aspects of the oil and gas industry and it should become an effective contributor to the sustainable development of the world in which we live.

It is common practice for Governments to make the granting of exploration concessions or production licenses to oil companies subject to the submission of a detailed environmental impact study and an overall business plan whose HSE component meets at least the requirements imposed by the Government.

In an oil project, from the early stages of exploration to production, EIA studies are required for seismic campaigns, the initial drilling and installation campaign for surface units, as well as the final stages of plant abandonment, including abandonment of oil rigs (also known as the decommissioning phase).

In summary, environmental impact studies are important for the following reasons:

EQS provides consultancy services in the preparation and analysis of environmental impact studies in the industrial, oil and gas and energy sectors.

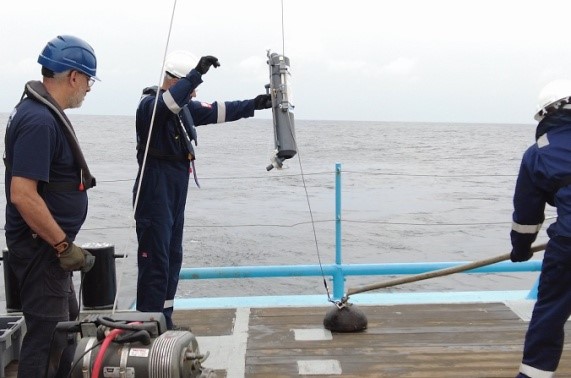

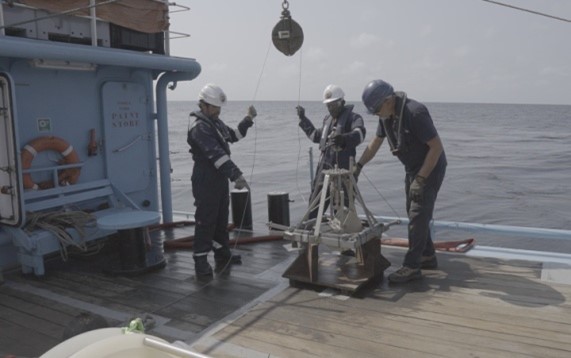

EQS has the ability and experience to carry out environmental monitoring of works. It is qualified to draw up field surveys, implementation of environmental management plans, construction and demolition waste prevention and management plans, as well as environmental and HSE audits.

This monitoring is assuming an increasingly important role for the promotion of a safer and more sustainable environment in the implementation of any industrial project. By a systematic collection of data on the state of the environment and issuance of the respective reports it will be possible to apply the measures deemed necessary for compliance with environmental regulations in force.

Within this monitoring are included the measurement of various physical and chemical parameters of Water and Sediments in order to assess their Quality.

In addition to these parameters, we can also highlight the capacity to carry out monitoring campaigns related to the characterization of macro benthic fauna, zooplankton and phytoplankton of a given project’s area of influence.

EQS offers services not only in the development and revision of Environmental Management Plans, but also in its effectiveness and monitoring.

Some of the environmental management plans addressed:

EQS is also capable of addressing and reviewing contingency plans, spill prevention and emergency response plans.

Naturally Occurring Radioactive Materials (NORM) originates in subsurface formations, and can be brought to the surface in formation water produced in conjunction with gas. Because the levels are typically so low, NORM in natural gas is typically not a problem unless it becomes concentrated. Produced waters may co-precipitate with barium sulfate scale or scale-bearing sludge, forming coatings or sediment in oil field equipment, including pipes, casings, fittings, tanks and basins. These solids become sources of oil and gas NORM-contaminated equipment and waste.

Furthermore, accumulation of NORM in gas stream sections of plant might occur due to the deposition of lead-210 which is a decay product of radon-222 contained in the natural gas. NORM with relatively high concentration of lead-210 might be found in gas filters and sludge produced during pipeline pigging.

Periodic NORM monitoring is recommended at a minimum frequency of prior to major facility maintenance shutdowns. NORM can then be removed in during maintenance shutdown events. If NORM is found to consistently accumulate at hazardous levels, more frequent monitoring of selected equipment is recommended. At this time, it is assumed scale removal would be required for facility performance, and that the presence of NORM is not the driving factor. The scales together with any other radioactive waste will be managed in accordance with national laws and good international industry practice.

In decommissioning projects, although the installation is no longer in service, it is most likely that, due to its operation nature, there is a chance NORM is present in specific equipment/structure. This supports the requirement to assess whether the facility is in a NORM free situation (or if present, mitigation actions are developed) allowing a safe decommissioning operation.

EQS provides services on the presence of NORMs (in collaboration).

Copyright EQS © All rights Reserved.

Headquarters: Unit 304 JBC1, Cluster G – JLT PO Box 334592 Dubai United Arab Emirates